Your Step-by-Step Guide to Launching a Welding Career

Introduction: Why Welding Is an Opportunity-Rich Career

Welding is a dynamic trade that offers strong job prospects, competitive pay, and the satisfaction of building and repairing essential structures. Whether you’re drawn to the hands-on nature of the work or the variety of industries it serves-from construction and manufacturing to aerospace and the arts-starting a welding career can be both practical and fulfilling. This guide delivers actionable steps, examples, and alternative routes to help you launch and grow your career in welding.

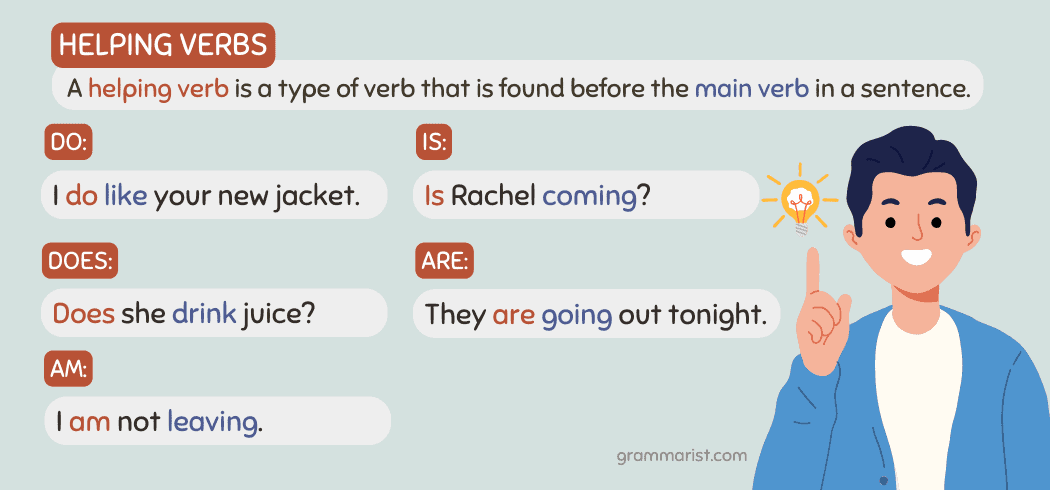

1. Understanding What Welders Do

Welders use specialized equipment to join metals together, interpreting blueprints and following strict safety codes. The field includes diverse roles such as structural welders, pipefitters, fabrication welders, underwater welders, and more. Each specialty requires a blend of technical skill, physical stamina, and attention to detail. Researching these options early on will help you choose a direction that fits your interests and strengths. For example, someone interested in travel and challenging environments might consider pipeline or underwater welding, while others may prefer fabrication in a shop setting. [2]

Source: flaticon.com

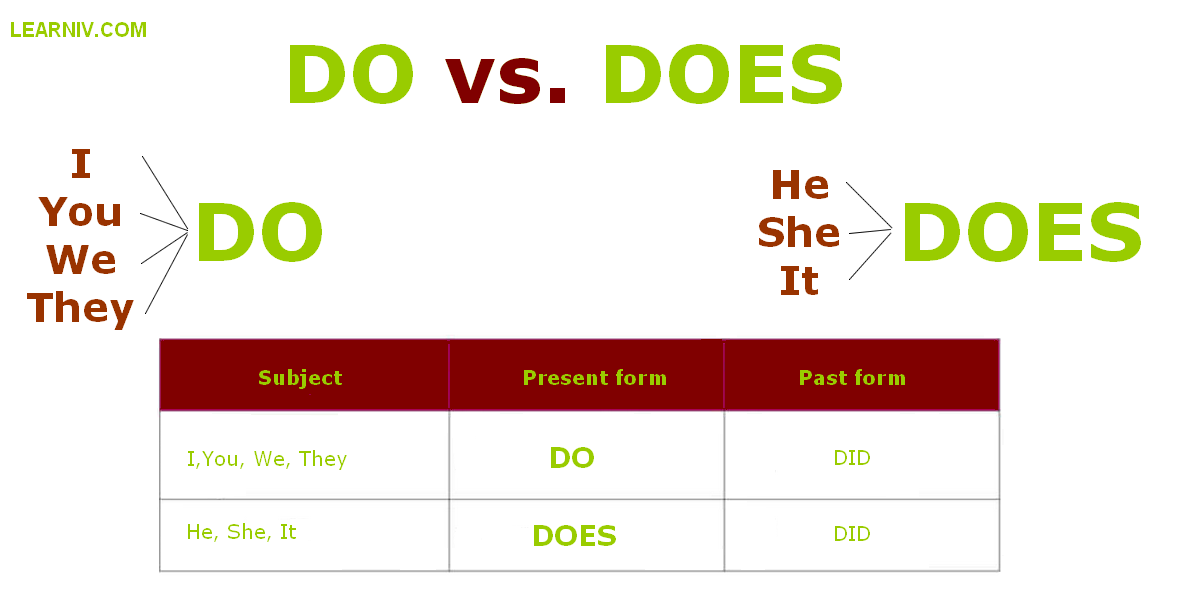

2. Meeting Minimum Education Requirements

Most welding careers require at least a high school diploma or GED. High school students can prepare by taking courses in math (especially geometry), science, and shop classes. These subjects provide the foundational knowledge needed for more advanced welding topics such as metallurgy and blueprint reading. [1] If your school offers welding classes, take advantage of them to gain early exposure. If you’re an adult without a diploma, obtaining a GED is a critical first step before pursuing technical training. [3]

3. Choosing the Right Training Path

There are several ways to prepare for a welding career. The path you choose depends on your learning style, location, and career goals.

Option 1: Vocational Training or Community College

Vocational schools and community colleges offer welding certificate or associate degree programs. Certificate programs typically last 6-18 months and focus on hands-on skills, safety, and the basics of welding technology. Associate degree programs, which take about two years, provide deeper knowledge in metallurgy, blueprint reading, and advanced techniques. [1] These programs usually include substantial lab time, allowing you to practice under supervision.

Option 2: Apprenticeships

An apprenticeship program combines paid, on-the-job training with classroom instruction. Apprenticeships are ideal for those who learn best by doing and want to earn an income while studying. You’ll work alongside experienced welders, building skills and earning credentials recognized by employers. [3] You can find apprenticeship opportunities by contacting local unions, trade organizations, or large employers in your area. Search online for “welding apprenticeships” along with your city or state for the most current openings.

Option 3: On-the-Job Training (OJT)

Some employers may hire entry-level workers and provide on-the-job training. This route is more common in regions with high demand for welders or in smaller shops. The training may be less formal and more limited than what vocational schools offer, but it allows you to start working-and earning-sooner.

Source: freepik.com

4. Earning Welding Certifications

Certification demonstrates that you meet industry standards and are qualified for certain types of welding work. Most employers require at least one recognized certification. The American Welding Society (AWS) offers several certifications, including the widely respected Certified Welder credential. [2] Certification typically involves passing written and practical exams. Some vocational and apprenticeship programs include AWS certification as part of their curriculum, while others will help you prepare but require you to test separately. To learn more about certification options and requirements, visit the American Welding Society’s official website or contact your training provider.

5. Gaining Practical Experience

Employers value hands-on experience. Internships, entry-level jobs, or freelance projects all help you build a portfolio and develop real-world skills. Many training programs include internships or job placements, but you can also seek out part-time work or volunteer opportunities with local fabricators, construction companies, or even art studios. Document your work with photos and references to showcase your abilities to future employers. [3]

6. Building In-Demand Skills

Successful welders have a blend of technical and soft skills. Key abilities include:

- Manual dexterity and hand-eye coordination

- Strong attention to detail

- Ability to read and interpret blueprints

- Knowledge of welding safety procedures

- Physical stamina and strength

- Problem-solving skills

Continuous learning is crucial, as new welding processes and materials regularly emerge. Workshops, seminars, and online courses can help you stay current. Networking with experienced welders through trade organizations or online forums is another way to learn about new techniques and job openings. [1]

7. Job Search Strategies

Once you have completed your training and earned certification, you can start your job search. Welding jobs are listed on major job boards, company websites, and through local unions or trade groups. Tailor your resume to highlight your skills, certifications, and hands-on experience. Prepare for interviews by being ready to discuss your training, safety record, and examples of successful projects. [2]

If you’re unsure where to begin, you can:

- Contact local manufacturers or construction companies to inquire about openings

- Reach out to trade unions and industry organizations for job leads

- Search for “entry-level welding positions” online in your area

Remember, some regions and industries offer higher pay and more job opportunities. Be open to relocating for the best positions, especially early in your career.

8. Advancing Your Welding Career

Welding offers clear opportunities for advancement. With experience, you can move into supervisory roles, become a welding inspector, or specialize in high-demand areas such as underwater or aerospace welding. Additional certifications and continuing education can open doors to these advanced positions. [1] Many welders also choose to start their own businesses, providing fabrication or repair services in their communities. Building a strong professional network and staying current with industry trends will help you identify new opportunities as they arise.

Potential Challenges and How to Overcome Them

Welding is physically demanding and may involve working in hot, confined, or hazardous environments. Proper safety training is essential to minimize risks such as burns, electrical shock, or exposure to fumes. Always follow industry safety standards and use personal protective equipment. If you encounter barriers to employment, such as limited job openings in your area, consider broadening your search or pursuing additional certifications to increase your competitiveness. [3]

Alternative Pathways

Not everyone’s journey into welding looks the same. Some enter the field through related trades, such as machining or metal fabrication. Others transition from military service, where welding skills are highly valued. If traditional schooling isn’t the right fit, you can still start as a helper or laborer and work your way up through on-the-job training, though this route may take longer and offer fewer advancement opportunities initially.

Key Takeaways and Next Steps

Welding is a versatile career with multiple pathways for entry and advancement. The most reliable way to get started is to pursue formal training and certification, gain hands-on experience, and keep learning throughout your career. If you’re ready to take the next step, research vocational programs or apprenticeships in your area. Contact the American Welding Society or your local community college for guidance on enrollment and certification requirements.