How Much of a Tesla is Made in America? A Deep Dive Into Tesla’s Parts and Manufacturing

Introduction: Understanding Tesla’s American Manufacturing Footprint

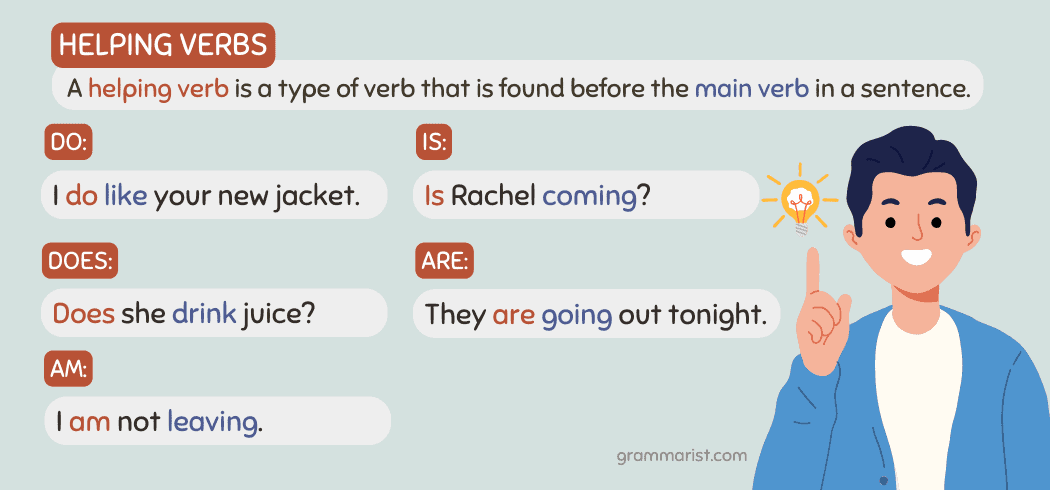

As Tesla continues to shape the landscape of electric vehicles (EVs), many consumers and industry watchers want to know: Are Tesla parts made in America? This question is crucial for those interested in supporting domestic manufacturing, understanding Tesla’s supply chain, and evaluating the company’s broader economic impact. This article provides a comprehensive look at where Tesla’s parts come from, the significance of its American factories, and what this means for buyers and advocates of U.S. manufacturing.

Source: sea.mashable.com

Tesla’s Core U.S. Manufacturing Facilities

Tesla maintains major manufacturing operations in the United States . The company’s original and largest vehicle assembly plant is the Fremont Factory in California, where the Model S, Model X, Model 3, and Model Y are assembled. Many core components for these vehicles are produced on-site or sourced from nearby suppliers. Tesla’s other significant U.S. facilities include:

- Gigafactory Nevada (Giga Nevada) : Specializes in battery packs, drivetrains, and energy products like the Powerwall. It is also home to the Tesla Semi assembly line [2] .

- Gigafactory Texas (Giga Texas) : Located in Austin, this factory produces Model Ys, with plans for Model 3, Cybertruck, and Semi production [3] .

- Gigafactory New York (Giga New York) : Focused on solar panels, energy products, and Supercharger equipment [3] .

These facilities highlight Tesla’s commitment to substantial American manufacturing, especially for vehicle assembly and high-value components such as battery packs and drivetrains.

Which Tesla Parts Are Made in America?

Many of the key components in Tesla vehicles are manufactured in the United States , particularly:

- Batteries and Drivetrains : The Gigafactory Nevada (in partnership with Panasonic) produces the majority of Tesla’s battery cells, packs, and electric drivetrains for vehicles assembled in the U.S. [2] .

- Vehicle Assembly : The Fremont and Texas factories assemble most Tesla vehicles sold in North America [1] .

- Structural Components : Many body, chassis, and interior components are produced in the U.S., often by suppliers located near Tesla’s factories to streamline logistics [1] .

However, it’s important to note that Tesla’s supply chain is global . Certain materials (such as rare earth metals for batteries) and electronic components may be sourced internationally. Some vehicle models-like those sold in Europe and Asia-are assembled in Tesla’s overseas Gigafactories, which also make some of the parts for those markets [2] .

How Tesla’s American Manufacturing Supports Local Industry

Tesla’s decision to locate major factories in the United States has a ripple effect throughout the local and national economy:

- Job Creation : Tesla’s American factories employ tens of thousands of workers-from line operators to engineers. This supports not only direct employment but also jobs at supplier companies and local businesses [1] .

- Supplier Ecosystem : Many suppliers have established facilities near Tesla’s U.S. factories to deliver just-in-time components, further contributing to American manufacturing [1] .

- Innovation and Training : Manufacturing in the U.S. drives investment in advanced automation, robotics, and workforce training, strengthening the country’s industrial base [4] .

For buyers who prioritize American-made products, Tesla’s U.S. manufacturing represents a strong commitment to domestic industry, but with the caveat that not every part is exclusively sourced from within the country.

Step-by-Step: How to Find Out Where Your Tesla’s Parts Were Made

If you want to know the specific origin of the parts in your Tesla, you can:

- Check the Window Sticker : New Tesla vehicles (like all cars sold in the U.S.) must display a Monroney label. This legally required sticker lists final assembly location and the percentage of U.S./Canadian parts by value. Review this sticker for details on American content.

- Review Tesla’s Manufacturer Disclosures : Tesla periodically publishes information about its supply chain and U.S. content. You can usually find this in their annual impact reports or SEC filings. Visit Tesla’s official website and search for “Impact Report” or “Supply Chain Transparency.”

- Contact Tesla Directly : You may contact Tesla’s customer service or visit a local Tesla store to request more details about your vehicle’s parts origin. Representatives can provide guidance on specific models or VINs.

- Search for Third-Party Analyses : Automotive industry sources and consumer organizations sometimes publish breakdowns of American content for major automakers. Searching for “Tesla American parts content” on credible automotive news sites can provide further insights.

While Tesla does not publish a full, official list of every supplier and part origin, these steps can help you understand your vehicle’s composition and the percentage of American-made content.

Challenges and Realities of Sourcing All Parts Domestically

Producing a vehicle entirely from American-made parts is challenging for any automaker, including Tesla. Key obstacles include:

- Global Materials Supply : Many raw materials, especially those for batteries (like lithium, cobalt, and nickel), are sourced globally due to limited domestic reserves.

- Cost and Specialization : Some components (such as semiconductors and specialized electronics) are produced more efficiently or exclusively outside the United States.

- Regulatory and Environmental Factors : Environmental regulations and cost constraints may make it impractical to source or manufacture certain parts domestically.

Despite these challenges, Tesla continues to invest in increasing the American content of its vehicles, and its U.S. Gigafactories are among the most advanced EV manufacturing sites in the world [2] .

Source: evmagz.com

Alternative Approaches for Consumers Seeking American-Made Vehicles

If your priority is supporting domestic manufacturing, consider the following steps:

- Research Vehicle Content : Use the American Automobile Labeling Act (AALA) database, which tracks the percentage of U.S./Canadian parts by value in each model sold in the U.S. The National Highway Traffic Safety Administration (NHTSA) maintains this database. To access it, visit the NHTSA’s official website and search for “AALA reports.”

- Ask Dealerships : When shopping for a car, ask the dealer for detailed information about U.S. parts content. This can be particularly helpful for comparing models and manufacturers.

- Review Annual Impact Reports : Many automakers, including Tesla, publish annual sustainability or impact reports with details on manufacturing locations and supply chain sourcing.

- Consider Used Vehicles : If a specific model year or assembly location is important to you, searching for used Teslas made in U.S. factories may increase the chance of higher American parts content.

Remember that no major automaker currently produces vehicles that are 100% American-made in terms of parts, but Tesla’s U.S. factories remain among the highest in domestic content for electric vehicles.

Key Takeaways: Tesla Parts, American Manufacturing, and What It Means for You

In summary, many Tesla parts are made in America , especially for vehicles assembled in Fremont, Texas, and Nevada. Key components such as batteries, drivetrains, and many structural parts are produced domestically, but some materials and electronics inevitably come from international sources. Tesla’s American factories boost local economies, foster innovation, and provide high-quality jobs, reinforcing the brand’s dedication to U.S. manufacturing. While not every part is American-made, Tesla’s impact on American industry remains significant and continues to grow as the company expands its domestic supply chain.

References

- [1] Electrek (2021). Tesla factory locations: Where they are and could soon be.

- [2] My Tesla Accessories (2024). Where Are Tesla Cars Made? Tesla Factories Around The World.

- [3] Capital One (2022). What You Need to Know About Tesla’s Gigafactories.

- [4] Tesla Hubs (2024). Where Is Your Tesla Made? A Guide to Tesla Manufacturing Locations.