Modern Solutions: What Has Replaced R-12 in Automotive Air Conditioning?

Understanding the Phaseout of R-12 in Automotive Air Conditioning

For decades, R-12 (also known by its trade name Freon-12) was the industry standard refrigerant in automotive air conditioning (A/C) systems. However, due to its ozone-depleting properties and high global warming potential, R-12 was banned for production and import in the United States and many other countries by the mid-1990s. This regulatory shift prompted a critical need for new refrigerants that would be both environmentally responsible and compatible with existing and new vehicles. This article details the leading replacements for R-12 , how to convert older systems, and what to consider when selecting a retrofit or new refrigerant.

What Refrigerant Has Replaced R-12 in Automotive Systems?

The primary replacement for R-12 in automotive applications is R-134a (1,1,1,2-Tetrafluoroethane). R-134a became the industry standard refrigerant for new vehicle production starting in the mid-1990s and is approved for use as a retrofit in most older R-12 systems. It is non-ozone-depleting and provides similar cooling performance, though it requires some system modifications for optimal reliability and efficiency [2] .

Source: meetrv.com

Why R-134a Was Chosen as the Standard Replacement

R-134a was selected after extensive industry and regulatory review because it offered a combination of chemical stability, safety (non-flammability), and reasonable efficiency. Importantly, it does not damage the ozone layer , addressing the core environmental concern with R-12. However, while R-134a’s global warming potential is lower than R-12’s, it is still significant, and efforts are ongoing to replace it with even lower-impact alternatives in the future.

Other R-12 Replacement Options

Beyond R-134a, several other refrigerants have been developed for older systems, including hydrocarbon-based blends (like Enviro-Safe, Red Tek, or Frosty Cool 12a) and HCFC-based blends (such as R-409A). These alternatives may be used in certain regions or specific applications where R-134a conversion is not feasible or desired. Each option has unique properties, benefits, and limitations, so it is critical to consider system compatibility, safety, and local regulations before selecting a replacement [1] [3] [4] .

Converting an R-12 System to R-134a: Step-by-Step Guidance

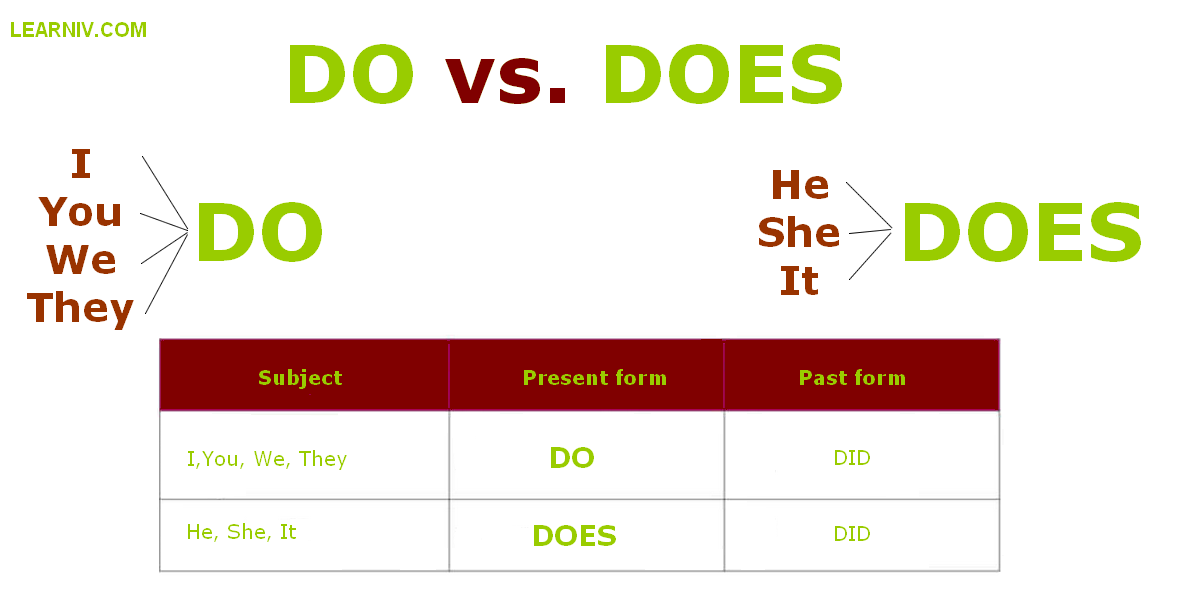

If you own a vehicle originally equipped with R-12, you have several options for keeping your A/C operational. The most common and widely supported method is to retrofit the system for R-134a . This process involves:

- Evacuating the old R-12 refrigerant : Any remaining R-12 must be recovered by a certified technician using approved equipment, as venting it is both illegal and environmentally harmful.

- Replacing lubricating oil : R-12 systems use mineral oil, which is not compatible with R-134a. The system needs to be flushed and recharged with a synthetic oil, typically PAG (polyalkylene glycol) or ester oil (POE), depending on the compressor and manufacturer recommendations [2] .

- Replacing critical components : Rubber hoses, seals, and accumulator/drier often need to be replaced with R-134a-compatible parts to prevent leaks and ensure long-term reliability. Retrofitting kits are available for many popular models.

- Installing R-134a service fittings and labeling : New fittings prevent accidental mixing of R-12 and R-134a and facilitate future servicing.

- Charging the system with R-134a : Once the system is properly prepared, it can be charged with R-134a. The charge amount is not a 1:1 replacement by weight-typically, 80-90% of the original R-12 weight is used. Always refer to the retrofit kit instructions or manufacturer guidelines.

It is highly recommended to have this process performed by a qualified automotive A/C technician who understands both environmental regulations and system compatibility.

Alternative R-12 Replacement Refrigerants: Pros, Cons, and Considerations

While R-134a remains the dominant replacement, some vehicle owners consider hydrocarbon-based blends (e.g., Enviro-Safe, Red Tek, Frosty Cool 12a) or HCFC-based blends like R-409A for older or specialty systems. These alternatives can offer lower conversion costs and, in some cases, require fewer system modifications. However, their use comes with important caveats:

Source: hunterdesignerhomes.com.au

- Hydrocarbon refrigerants (like Enviro-Safe) are flammable and may not be legal in all regions or suitable for all vehicles. They can sometimes work with the existing mineral oil and require less system modification, but always check local regulations and manufacturer guidelines [3] .

- HCFC-based blends (such as R-409A) are less flammable but are themselves subject to phaseout under environmental regulations. Their long-term availability may be limited, and they may not be the best option for future-proofing your A/C system [1] .

- System compatibility is critical-some blends may not perform optimally in all climates or with all compressors. Performance, efficiency, and reliability can vary based on system design and age [4] .

Practical Considerations: Parts Availability, Cost, and Long-Term Service

R-134a remains widely available, relatively affordable, and supported by most automotive service shops. Retrofit kits and replacement parts are produced for a wide range of vehicles, making this the most reliable long-term solution. Hydrocarbon and HCFC blends may be harder to source, with uncertain regulatory status, especially as environmental regulations continue to tighten worldwide.

If you are seeking to maintain your classic or vintage car’s A/C system, consider the following steps:

- Consult a local, reputable automotive A/C service center to assess your system’s condition and compatibility for retrofit.

- Ask about the availability of R-12 (legal only for certified professionals and expensive) versus R-134a or approved blends.

- Review your local and state regulations concerning refrigerant use and conversion.

- Request a quote for the full retrofit process, including all necessary parts, fluids, and labor.

- If you choose an alternative refrigerant, verify it is legal, safe, and supported by your vehicle’s manufacturer or a reputable aftermarket supplier.

How to Access R-12 Replacement Services and Support

To convert or repair your vehicle’s air conditioning system, you can:

- Search for “automotive air conditioning retrofit service” in your area or contact your vehicle manufacturer’s authorized service network.

- Verify that your chosen technician is certified in mobile air conditioning service (often referred to as Section 609 certification in the U.S.).

- If you are a do-it-yourselfer, follow step-by-step guides provided by established automotive parts suppliers and ensure you use only approved retrofitting kits.

- For technical guidance, consult resources from the U.S. Environmental Protection Agency (EPA) by searching for “EPA mobile air conditioning refrigerant information” or reviewing the EPA’s official website. The EPA provides comprehensive information on regulatory compliance, proper retrofitting procedures, and environmental best practices.

- If you are seeking to purchase refrigerant, only do so from authorized, reputable suppliers. Note that in the U.S., purchasing R-12 or R-134a for automotive use typically requires proof of certification due to regulatory restrictions.

For further assistance, you can contact industry organizations such as the Mobile Air Climate Systems Association (MACS) or your local automotive repair association for referrals to qualified service providers.

Alternatives and Future Trends in Automotive Refrigerants

While R-134a remains the dominant replacement, newer refrigerants with much lower global warming potential are being introduced. For example, R-1234yf is now used in many new vehicles and is designed to be even more environmentally friendly. Retrofitting older R-12 systems to R-1234yf is generally not recommended or supported due to technical and safety differences, but it signals the direction of future standards.

Key Takeaways and Action Steps

R-134a is the most widely accepted and supported replacement for R-12 in automotive systems. Retrofitting requires careful attention to component compatibility and regulatory requirements. Alternative refrigerants exist but require additional research and caution due to varying legal status and safety concerns. Always consult a qualified professional and refer to official guidance when planning a conversion or repair.

References

- [1] Freonâ„¢ 409A (R-409A) Refrigerant | R-12 Retrofit (n.d.). Freon.com: Official manufacturer information about R-409A as an R-12 retrofit option.

- [2] Automotive Air Conditioning Information Forum (2023). Community discussion on R-12 replacement and retrofit practices.

- [3] Car Air Conditioning R12 Replacement Does it Work? (2023). YouTube demonstration on R-12 alternatives.

- [4] Grassroots Motorsports Forum (2020). User experiences and recommendations for modern R-12 replacements.