Mastering Safe Wire Removal from Automotive Connectors: Step-by-Step Expert Guide

Introduction

Automotive connectors are critical to a vehicle’s electrical system, linking vital components such as lighting, sensors, ECUs, and entertainment units. Over time, the need to remove wires from automotive connectors arises for repairs, modifications, or troubleshooting. However, improper removal can damage both the connectors and wiring, leading to costly repairs or unsafe conditions. This detailed guide covers the safest, most reliable methods for wire removal, the tools required, alternative approaches, real-world examples, and troubleshooting strategies-all based on current industry standards and verified resources.

Understanding Automotive Connectors

Automotive connectors are engineered to provide secure electrical connections while also allowing for disassembly when maintenance or upgrades are necessary. Most connectors use terminal pins that lock into plastic housings via small plastic tabs or metal barbs. Manufacturers design these locking systems to prevent accidental disconnection but also allow for controlled release using specific tools. Understanding the mechanism of your specific connector type is essential before attempting removal, as approaches can vary across brands and models.

Essential Tools for Safe Wire Removal

To safely and effectively remove wires from automotive connectors, professionals recommend assembling the following tools:

- Terminal Pin Removal Tool or De-pin Release Tool: Purpose-built for releasing pins from connector housings, these come in various shapes and sizes to match different connector types. Popular models include the iCrimp IWS-123D DT Series Terminal Extraction Tool Kit, among others [1] .

- Small Flat-blade Screwdriver: Essential for releasing locking latches or pin lock retainers on many connectors. Insulated screwdrivers are preferred for added safety [1] .

- Safety Glasses: Protect your eyes from debris or sparks when working with automotive electrical systems [1] .

- Insulated Gloves (Optional): Offer extra protection against accidental electric shock, especially when working on live circuits.

Safety Precautions

Before beginning any wire removal process, always disconnect the vehicle’s battery to eliminate the risk of short circuits or electrical shock. Working with live circuits can be hazardous, so use gloves and safety glasses for additional protection. If unsure about the procedure or if the connector is part of a critical system (such as airbags or engine management), consider consulting a professional technician.

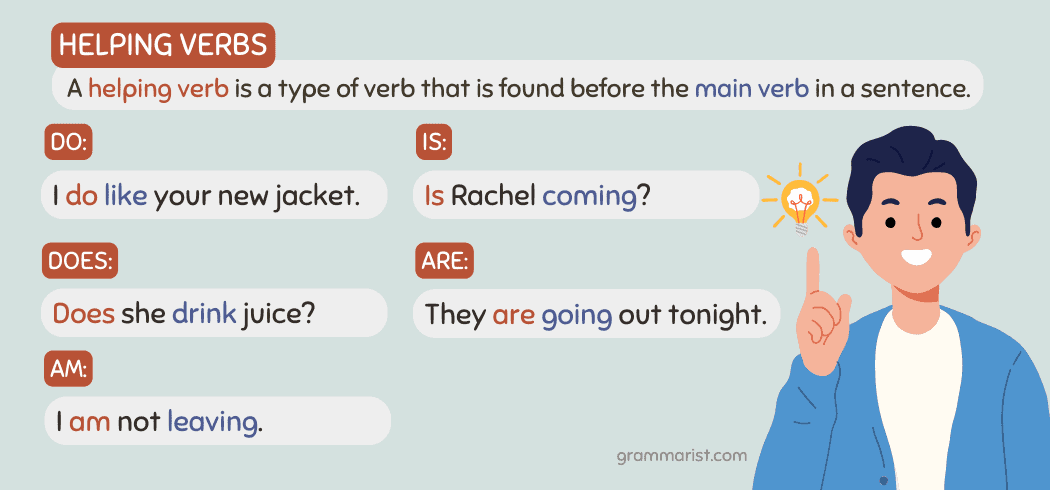

Source: storage.googleapis.com

Step-by-Step Guide: Removing Wires from Automotive Connectors

The following procedure outlines the standard steps for most automotive connectors. Always refer to your vehicle’s service manual for model-specific details.

Step 1: Inspect the Connector

Begin by closely examining the connector to identify the locking mechanism. Most connectors have a visible catch, tab, or secondary lock that secures the terminal pins [2] . Use a flashlight if necessary to see the internal structure.

Step 2: Release the Locking Tab

Use the appropriate terminal removal tool or a small flat-blade screwdriver to carefully pry up, push in, or press the locking catch as required by the connector design. The goal is to release the lock that holds the pin in place [2] . It is critical to maintain pressure on the catch while extracting the wire; releasing the catch prematurely causes it to re-lock, potentially damaging the connector or wire.

Step 3: Gently Extract the Wire

While holding the locking catch open, use your other hand to slowly and gently pull the wire from the rear of the connector. If resistance is encountered, double-check that the lock is fully disengaged. Avoid excessive force, as it can break the plastic catch or deform the terminal pin.

Step 4: Inspect and Reassemble

After removal, inspect both the wire and connector for any damage. Before reassembly or pin reinsertion, ensure that the locking tab is reset and the connector housing is intact. Minor deformation of the terminal pin can often be corrected with needle-nose pliers, but replace any part that appears significantly damaged.

Source: findpigtails.com

Example: Removing Pins from a Push-In Automotive Connector

For push-in connectors, such as those found in headlight assemblies or sensor harnesses, the removal process typically involves:

- Locating the small plastic tab or metal barb that holds the pin in place.

- Inserting the terminal removal tool to disengage the locking mechanism.

- Maintaining pressure on the release while gently pulling the wire from the rear.

This procedure is frequently demonstrated in training resources and industry tutorials [2] .

Potential Challenges and Solutions

Wire removal can present challenges, including:

- Broken Locking Tabs: If a plastic catch breaks during removal, replacement connectors or repair kits are typically available from auto parts suppliers. In some cases, creative use of zip ties or heat-shrink tubing may temporarily secure connections, but permanent repairs are recommended.

- Stuck or Deformed Pins: Gently realign bent pins using pliers. If a pin cannot be removed, double-check the locking mechanism and repeat the release process with adequate lighting and the correct tool.

- Unusual Connector Designs: High-end vehicles or specific systems (such as airbag modules) may use proprietary connectors. When in doubt, consult the vehicle’s service manual or a dealership for guidance.

Alternative Approaches and Troubleshooting

While most removals use dedicated tools, some professionals use modified paper clips or sewing needles in emergency situations. However, these improvised tools are more likely to damage the connector and should only be used with caution. For connectors that refuse to release, applying a small amount of electrical contact cleaner may help loosen debris, but always allow chemicals to dry fully before restoring power.

If you encounter persistent difficulties or suspect connector damage, professional automotive electricians can perform advanced repairs or supply replacement parts. Local auto parts stores and online retailers often carry a variety of extraction tools and replacement connectors compatible with most vehicle makes and models.

Accessing Additional Resources and Professional Support

If you need more guidance on specific connector types or wish to purchase professional-grade removal tools, you can search for automotive electrical tool suppliers or visit major parts retailers. For detailed vehicle-specific instructions, your best option is usually the official repair manual for your car’s make and model, available from dealerships or through authorized online manual vendors. Many reputable suppliers, such as iCrimp and FindPigtails, provide training materials and tool recommendations [1] [2] .

For real-time demonstrations, instructional videos on YouTube-such as those from automotive repair experts-offer visual step-by-step guides. Always verify the credibility of the video creator and ensure the method aligns with your specific connector style [3] [4] .

Summary and Key Takeaways

Successfully removing wires from automotive connectors requires patience, the right tools, and an understanding of the locking mechanisms involved. By following the outlined steps, observing safety precautions, and using the recommended tools, you can avoid damage and ensure reliable repairs or modifications. For unusual connectors or persistent problems, consult a professional or seek model-specific guidance from manufacturer resources. With careful technique and the best practices described here, you can maintain your vehicle’s electrical integrity and safety.

References

- iCrimp Tools (2023). How to Remove Pins from Automotive Electrical Connectors.

- FindPigtails (n.d.). How To Remove Wire Pins From Push-In Automotive Connector.

- YouTube – Technically Speaking (2020). How To De-pin Connectors.

- YouTube – Motion Raceworks (2024). Automotive Wiring Connectors 101: Tech Tip Tuesday.